Online Robot Programming vs Offline Robot Programming

Offline programming involves creating robot programs through a computer using programming software and a simulated work environment. Unlike online programming methods, offline robotic programming does not require the robot to be present.

What’s the Difference Between Offline Programming and Simulation?

Jun 19, 2019 · Offline programming refers to the practice of programming a machine (usually a robot or a CNC machine) without having the physical machine present. In other words, you first create the program on a computer and then later download it to the physical machine later.

Robot offline programming (OLP): the complete guide (with …

Jun 15, 2023 · This is your complete and comprehensive guide to offline robot programming (OLP). After introducing the topic, it addresses common misconceptions, the problems it resolves, benefits, and real-life example of its successful implementation.

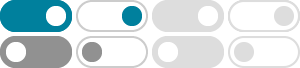

What to choose: On-line or Off-line Programming? - Xeltek

What are the advantages and disadvantages of online and offline programming? This is a problem faced by many companies and engineers.This article will make this simple analysis and make it easier for you to choose best solution for your application.

Online vs. Offline Robot Programming – Which One to Choose …

Apr 25, 2023 · Choosing the right programming method for your application among the many possible alternatives depends on several factors (there is no one-size-fits-all method). We will introduce and compare the most popular online and offline methods used …

What Are the Different Programming Methods for Robots?

Mar 24, 2016 · Offline programming, or simulation, is most often used in robotics research to ensure that advanced control algorithms are operating correctly before moving them onto a real robot. However, it is also used in industry to reduce downtime and improve efficiency.

Programming Industrial Robots: Offline vs. Online

Nov 5, 2024 · Choosing between offline and online programming depends on the specific needs and resources of a manufacturing operation. Offline programming offers efficiency and safety benefits for complex tasks, while online programming provides simplicity and immediacy for straightforward applications.

Recent progress on programming methods for industrial robots

Apr 1, 2012 · In practical industrial applications, today there are two main categories of robotic programming methods, which are, online programming (including lead-through and walk-through) and offline programming (OLP) [1].

What Is the Best Way to Program a Robot? - RoboDK blog

Oct 9, 2018 · For practical applications in industry, you have basically got two categories of robot programming: Online programming — This involves stopping the robot from its productive work and switching it to “programming mode.” Then, you …

Easy online & offline robot programming | ArtiMinds Robotics

One software for all phases | seamless switch between online & offline robot programming | manufacturer independent | only with ArtiMinds

- Some results have been removed